When you press the brake pedal, your vehicle slows down or comes to a stop almost instantly. This everyday action might seem simple, but it relies on a complex interplay of forces, materials, and engineering principles. At the core of this process are your car’s brake pads, components that are essential to safe driving and effective stopping.

While most drivers know they need to replace these parts periodically, fewer understand how they work or why the type and condition of their pads matter so much. In this article, we’ll break down the science behind them, from the physics of friction to the materials used in manufacturing, and how they work in concert with other braking components to keep you safe on the road.

The Basic Mechanics of Braking

To understand how a vehicle slows down, it helps to start with basic physics. When you’re driving, your car has kinetic energy, the energy of motion. In order to bring the vehicle to a stop, that kinetic energy must be dissipated. This is where the braking system comes in.

Brake pads are part of a disc braking system, which also includes a rotor (disc), calliper, and hydraulic components. When you press the brake pedal, the calliper pushes the pads against the spinning rotor, creating friction. That friction converts the car’s kinetic energy into heat energy, which is then dispersed into the surrounding air.

This heat dissipation is crucial. The more efficiently a braking system can convert kinetic energy into heat and get rid of that heat, the more effective it is at bringing a vehicle to a stop.

Friction: The Science Behind Stopping Power

Friction is the central principle behind how these parts work. Specifically, two types of friction are at play: static and kinetic. Static friction helps initiate the braking process, while kinetic friction continues the process of deceleration.

The coefficient of friction is a numerical value that indicates how much grip one surface has against another. High-performance brake pads are engineered to have a high coefficient of friction to maximize stopping power. However, too much friction can cause excessive wear or noise, while too little can reduce braking effectiveness.

Manufacturers carefully balance these values to create products that perform well under different conditions, whether that’s stop-and-go traffic, highway speeds, or emergency braking situations.

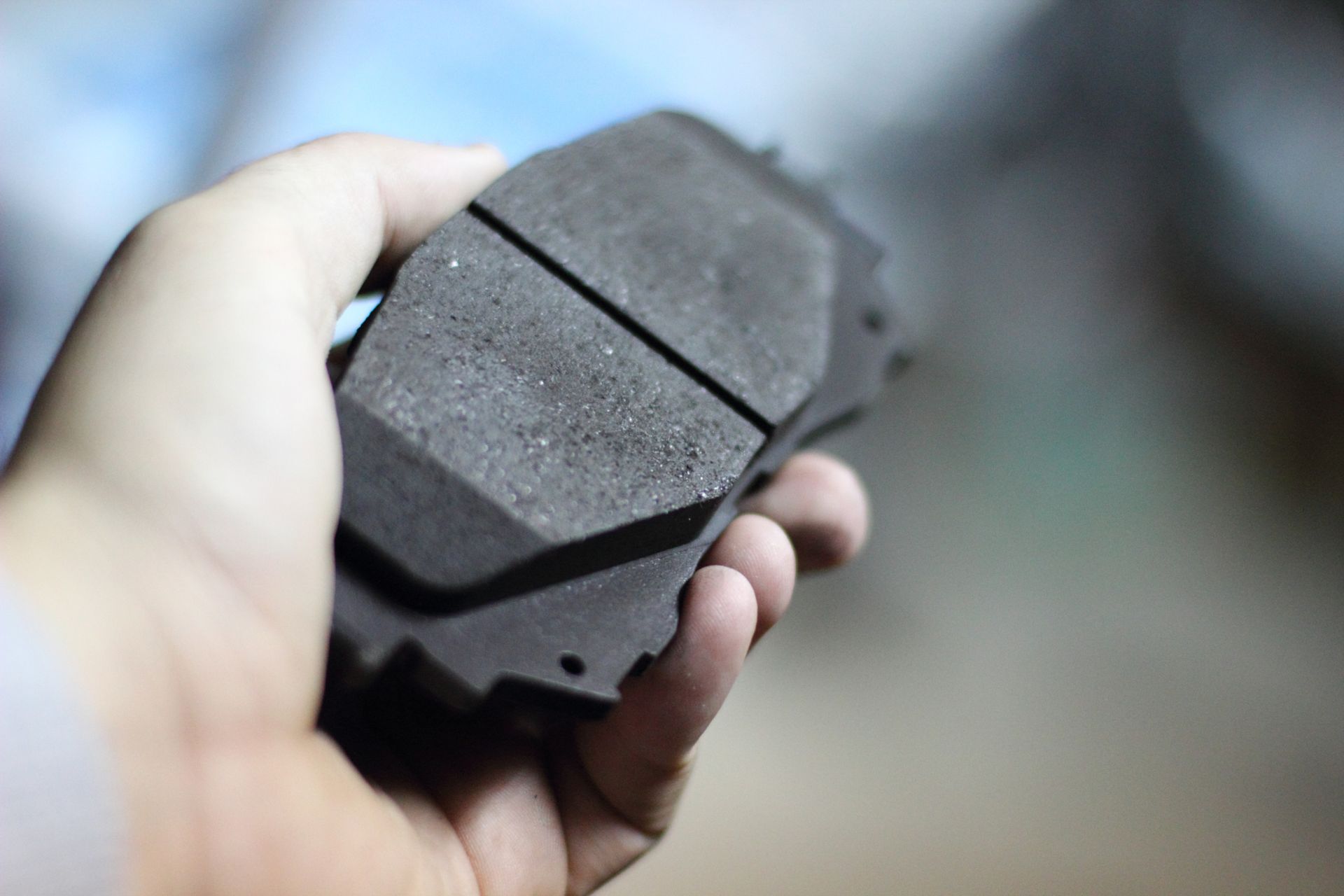

Materials Matter: Types of Brake Pad Compositions

Not all pads are created equal. In fact, the type of material used has a big impact on performance, longevity, noise level, and heat management. There are four primary types of brake pad materials:

1. Organic (Non-Asbestos Organic or NAO):

These are made from a mix of fibres, resins, and fillers. They are quiet and produce less dust but wear out faster and are not ideal for high-performance or heavy-duty applications.

2. Semi-Metallic:

Composed of metal shavings (like steel or copper) combined with resin, these offer excellent performance and heat resistance. However, they can be noisy and may wear down rotors more quickly.

3. Ceramic:

Made from ceramic fibres and nonferrous filler materials, ceramic pads offer a great balance of longevity, low dust production, and quiet operation. They’re more expensive but ideal for most passenger vehicles.

4. Low-Metallic NAO:

These are similar to organic versions but include a small amount of copper or steel for improved heat transfer and braking ability. They can be noisier and generate more dust than ceramic options.

Each type has its pros and cons, and the right choice depends on driving habits, vehicle type, and performance expectations.

Heat: A Critical Factor in Brake Pad Performance

As mentioned earlier, the braking process generates heat, and lots of it. During hard or prolonged braking, such as going downhill or stopping from high speeds, temperatures can exceed 500°C (932°F).

Brake pads are engineered to withstand these high temperatures, but their performance can still degrade if the heat isn’t managed effectively. This condition is known as brake fade. When overheating occurs, the friction material may lose its grip, resulting in longer stopping distances and reduced control.

To combat this, manufacturers incorporate heat-resistant resins, design cooling grooves into the pads, or use metal backing plates to transfer heat away from the contact surface.

Wear and Tear: How Brake Pads Break Down Over Time

Like tires or wiper blades, these components wear out with use. Every time you hit the brakes, a tiny amount of material is worn off. Eventually, they become too thin to function safely.

Several factors influence how quickly they wear down:

- Driving habits: Aggressive braking or frequent stop-and-go driving accelerates wear.

- Terrain: Hilly or mountainous areas require more braking, leading to quicker deterioration.

- Load: Heavier vehicles or towing can increase the demand on your braking system.

Most modern pads include a built-in wear indicator, which produces a high-pitched squeal when they need to be replaced. Some vehicles also have electronic sensors that alert you via a dashboard light.

Noise and Vibration: The Role of Damping

Noise is a common complaint when it comes to braking systems. Squealing or grinding sounds are often the result of vibration between the pad and other components, like the calliper or rotor. Manufacturers use shims, lubricants, and specialized backing plates to dampen these vibrations and reduce noise.

In high-performance applications, anti-rattle clips and insulators are also used to keep the braking system quiet and smooth. However, not all noise is a cause for concern. Some pads, especially semi-metallic types, naturally make more sound due to their composition.

The Role of the Rotor

While the focus here is on brake pads, it’s important to recognize that they don’t work in isolation. The rotor plays a crucial role in the braking process by providing the surface against which the pads clamp down.

If a rotor is warped, uneven, or worn, it can cause pulsation, reduced efficiency, or uneven wear on the pads themselves. For optimal performance, rotors should be inspected and either resurfaced or replaced as needed when new pads are installed.

Advances in Brake Pad Technology

As automotive technology evolves, so do the materials and engineering methods behind braking components. Recent advancements include:

- Copper-free formulations: To reduce environmental impact, many manufacturers are shifting to copper-free materials without sacrificing performance.

- Low-dust compounds: New formulations produce less brake dust, helping keep wheels cleaner and reducing airborne particles.

- Noise-reducing technologies: Enhanced shims, multi-layer backing plates, and advanced lubricants are improving the driving experience by minimizing squeal and vibration.

- Improved temperature resistance: High-performance cars now use pads that can handle extreme heat without fading, ideal for track use or heavy-duty applications.

Choosing the Right Brake Pads

Selecting the appropriate type for your vehicle isn’t just about price; it’s about performance, safety, and comfort. Factors to consider include:

- Driving environment: City driving requires different stopping power than highway or mountainous terrain.

- Vehicle type: SUVs and trucks often need semi-metallic or heavy-duty options, while sedans may benefit from ceramic versions.

- Budget and lifespan: While ceramic pads may cost more upfront, they often last longer and offer a quieter ride.

Always consult your vehicle’s manual or a trusted mechanic to ensure you’re using the right type for your specific needs.

When to Replace Your Brake Pads

Knowing when to replace these parts can prevent larger problems and keep you safe. Signs they may be due for replacement include:

- Squealing or grinding noises

- A soft or spongy brake pedal

- Increased stopping distance

- Vibration when braking

- A dashboard warning light

Most should be replaced every 50,000 kilometres, but this can vary based on usage. Regular inspections, especially during tire changes, can help identify wear before it becomes dangerous.

Final Thoughts

Brake pads are far more than just replaceable car parts; they are precision-engineered components designed to manage intense heat, friction, and pressure. Understanding how they work, what materials they’re made from, and how they wear over time can help you make informed choices about maintenance and replacement.

Whether you’re a daily commuter or a weekend road-tripper, properly functioning brake components are essential for your safety and the overall performance of your vehicle.

Stay Safe and Stop with Confidence at TrilliTires

At TrilliTires in Richmond Hill, we offer expert inspections, quality brake pad replacements, and complete brake system services to keep your vehicle safe and reliable. Book your appointment today and experience smooth, worry-free driving every time you hit the brakes.