Understanding What Causes a Car to Idle

When you turn on your car and it runs without moving, this process is known as idling. It’s something most drivers experience every day, whether you’re warming up the engine, stuck at a red light, or sitting in traffic. But have you ever stopped to think about why this happens or what it means for your vehicle’s health and efficiency?

While the concept of a car engine running while the vehicle remains stationary might seem simple, there’s actually quite a bit going on under the hood. Let’s take a deeper look at the mechanics, causes, and concerns related to this behaviour.

How the Engine Works at Idle Speed

When your engine is idling, it’s still working, just at a low speed. The throttle is closed or almost closed, and the engine control unit (ECU) adjusts the air-fuel mixture and ignition timing to keep it running smoothly. This process allows essential systems like the power steering, alternator, and air conditioning to function even when the vehicle is not moving.

Modern engines are equipped with sensors and computer systems that maintain a steady idle speed, usually between 600 and 1,000 revolutions per minute (RPM). If the engine runs too fast or too slow while idle, it could point to an underlying issue.

Common Reasons a Car Might Idle Roughly or Abnormally

While idling is a normal part of how a car operates, unusual idling behaviour can be a sign of a problem. Here are some typical reasons this might happen:

1. Faulty Spark Plugs

Spark plugs ignite the air-fuel mixture in the engine. If they’re dirty or worn out, combustion becomes inefficient, which may cause the engine to misfire or idle unevenly.

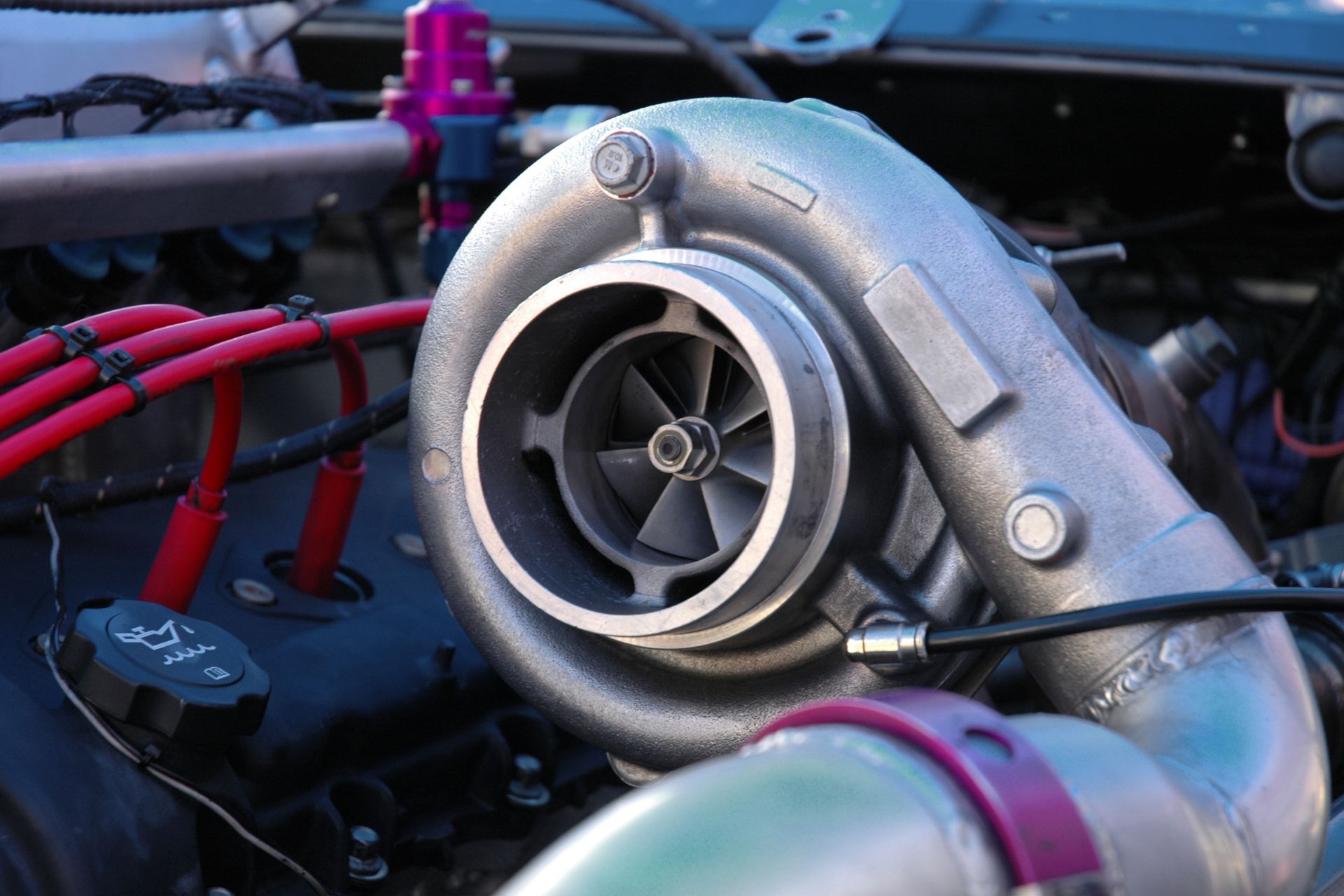

2. Vacuum Leaks

Your engine relies on a sealed system to manage airflow. If there’s a leak in one of the vacuum hoses, too much air can enter the system, disrupting the air-fuel ratio. This often results in high or erratic idling.

3. Dirty or Failing Idle Air Control Valve

This valve is responsible for maintaining the proper amount of air during idling. If it becomes dirty or stuck, it can prevent the engine from maintaining a consistent idle speed.

4. Malfunctioning Mass Air Flow Sensor

This sensor measures the amount of air entering the engine. If it’s not working correctly, the ECU may miscalculate the fuel needed, leading to poor idling performance.

5. Fuel System Issues

Problems with the fuel injectors, fuel pump, or fuel filter can cause inconsistent delivery of fuel, leading to rough or sputtering idle conditions.

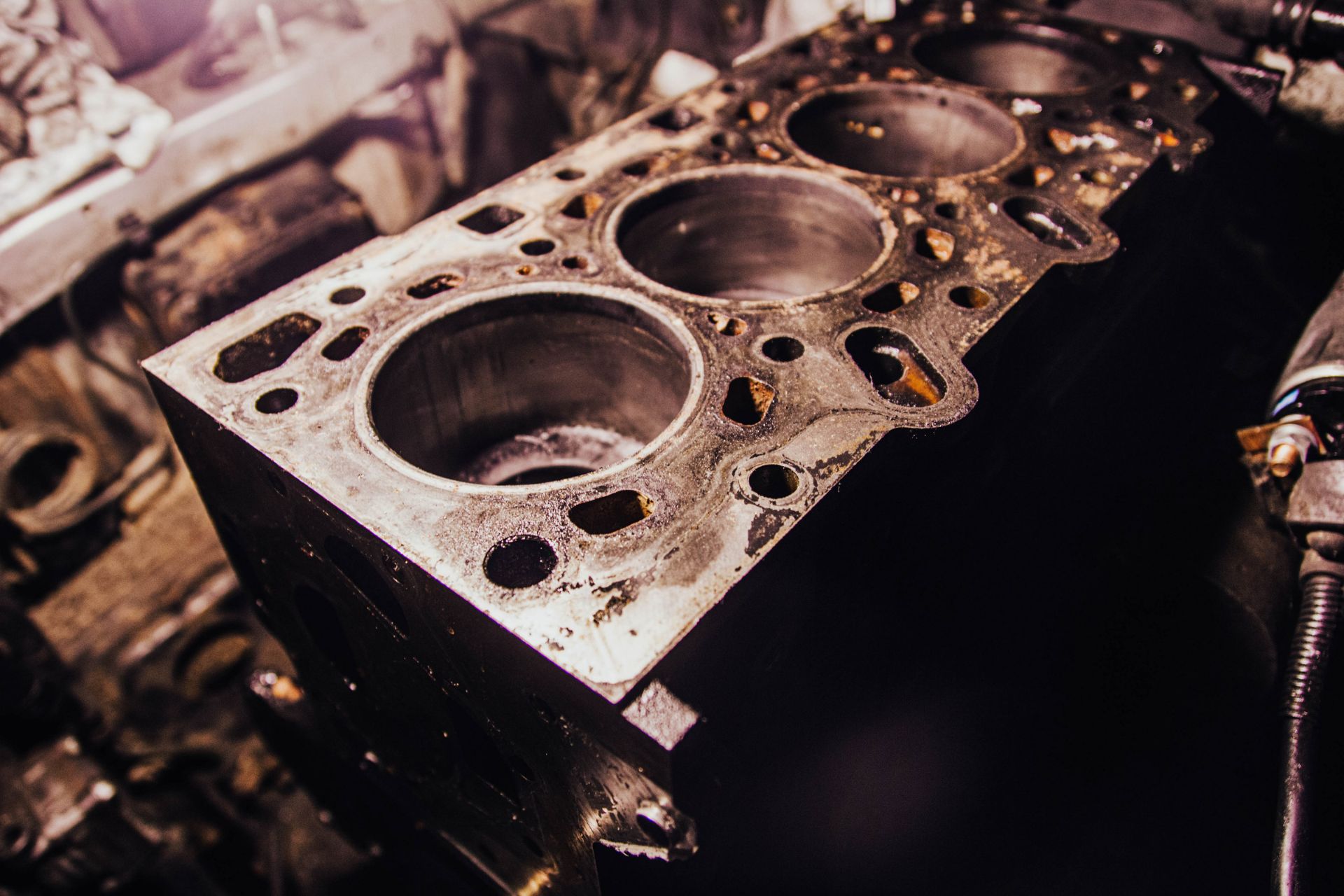

6. Engine Temperature Problems

The engine temperature sensor tells the ECU how hot the engine is, affecting how much fuel it injects. A faulty reading can cause improper idling, especially when the engine is cold.

Why Some Engines Idle Higher Than Normal

It’s not uncommon for engines to idle at a higher RPM during a cold start. This is a programmed function to help the engine warm up faster. However, if your vehicle continues to idle high even after warming up, it could be due to:

- A stuck throttle plate

- Faulty idle control system

- Leaking intake manifold gasket

- Incorrect adjustments or settings in the ECU

High idle speeds can waste fuel and increase wear on the engine over time.

The Environmental and Mechanical Impact of Excessive Idling

While short periods of idling are generally harmless, excessive idling can have both environmental and mechanical downsides. From an environmental perspective, unnecessary idling contributes to air pollution and increased greenhouse gas emissions.

Mechanically, prolonged idling can cause:

- Carbon build-up inside the engine

- Poor fuel economy

- Faster degradation of engine oil

- Overheating in some cases, especially in older vehicles

Reducing idle time not only helps your engine last longer but also benefits the planet.

When to Be Concerned About Your Car’s Idle

If your car begins to idle roughly, too high, too low, or stalls while idling, it’s time to have it checked. Warning signs to watch out for include:

- Shaking or vibrating while the engine is running

- The engine stalls at red lights or when parked

- Unusual noises such as knocking or pinging

- Dashboard warning lights, especially the check engine light

These symptoms could indicate something simple, like a dirty air filter or something more complex, such as a sensor failure or engine vacuum leak.

How to Maintain a Healthy Idle

Preventing idle-related problems is often a matter of regular maintenance. Here are a few tips to keep your car idling smoothly:

- Replace spark plugs as recommended by your manufacturer

- Check and replace the air filter regularly

- Clean the throttle body and idle control valve

- Keep up with fuel system cleaning services

- Address any check engine light issues promptly

By taking these steps, you can help ensure your car idles efficiently and avoid unnecessary repair costs.

Modern Tech: Stop-Start Systems

Many newer cars come with automatic stop-start systems designed to reduce idle time. These systems shut off the engine when the car is stopped and restart it when the accelerator is pressed. This helps improve fuel efficiency and reduce emissions. If your vehicle has this feature, it’s essential to ensure that it’s functioning correctly. A malfunction could lead to frequent stalls or longer restart times.

Should You Let Your Car Idle to Warm Up?

One of the most debated topics around this behaviour is whether or not you should let your car idle to warm up, especially in cold weather. With older carbureted engines, warming up was necessary. However, modern fuel-injected engines warm up more efficiently when driving.

Letting your car idle for more than 30 seconds to a minute in most conditions is generally not recommended. It wastes fuel and can contribute to unnecessary engine wear. Instead, drive gently for the first few minutes to allow the engine to warm up under load.

In Summary

Idling is a normal function of your car’s engine, but changes in how your car idles can be an early sign of underlying mechanical issues. Understanding what causes your engine to idle and recognizing when things are off can help you maintain your vehicle’s health and avoid costly repairs down the road.

If you’re noticing any issues with how your car idles, whether it’s stalling, shaking, or running too high or too low, it’s important to have it checked by a trusted mechanic.

Need expert help? Visit TrilliTires in Richmond Hill for professional diagnostics and repair services. Your car deserves top-quality care. Book your service today.